Key Takeaways

✅ Stegra is one of the world’s first green hydrogen-powered steel plants.

✅ It aims to reduce CO2 emissions by up to 95%.

✅ The project will create thousands of jobs and boost the Swedish economy.

✅ Green hydrogen replaces coal, producing only water vapor.

✅ A potential model for global decarbonization of heavy industry.

✅ Stegra is one of the world’s first green hydrogen-powered steel plants.

✅ It aims to reduce CO2 emissions by up to 95%.

✅ The project will create thousands of jobs and boost the Swedish economy.

✅ Green hydrogen replaces coal, producing only water vapor.

✅ A potential model for global decarbonization of heavy industry.

The global steel industry is one of the largest contributors to greenhouse gas emissions, accounting for roughly 7–9% of global CO2 emissions. With mounting climate concerns, Sweden is charting a new course to revolutionize how steel is produced. The Stegra steel plant project, recently announced by Swedish authorities and industrial leaders, marks a major leap toward clean energy-powered industrial manufacturing. What sets it apart? It aims to harness green hydrogen—a non-polluting energy source derived from renewable electricity—to decarbonize steel production at scale.

This blog takes a deep dive into the Stegra project, its technological underpinnings, environmental significance, and the ripple effects it could create for jobs, the economy, and the future of industrial sustainability.

The Need for Change: Steel Industry and Climate Crisis

Emissions from Traditional Steelmaking

Traditional steel manufacturing relies heavily on coal-based blast furnaces. These furnaces not only consume vast amounts of energy but also emit large quantities of CO2 due to the chemical reaction between carbon and iron ore. In a typical blast furnace:

Iron ore (Fe2O3) is reduced by coke (a coal derivative).

This process emits carbon dioxide as a byproduct.

With the steel industry alone producing over 1.8 gigatons of CO2 annually, finding sustainable alternatives is no longer optional—it is urgent.

Enter the Stegra Steel Plant: A Game-Changing Project

What Is the Stegra Project?

The Stegra steel plant, located in northern Sweden, is poised to become one of the world's first large-scale green steel facilities. The project has been backed by a coalition of government agencies, private investors, and renewable energy providers, aiming to produce fossil-free steel by using green hydrogen instead of coal.

Key Features:

Green Hydrogen Utilization: The plant will replace coke with hydrogen in the direct reduction process.

Powered by Renewable Energy: Electricity from Sweden's wind, hydro, and solar sources will power the electrolysis of water to create hydrogen.

Carbon-Neutral Target: Designed to emit zero CO2 during the iron reduction phase.

Job Creation: Estimated to generate over 10,000 direct and indirect jobs.

Location Synergy: Proximity to renewable energy hubs and ports for logistical efficiency.

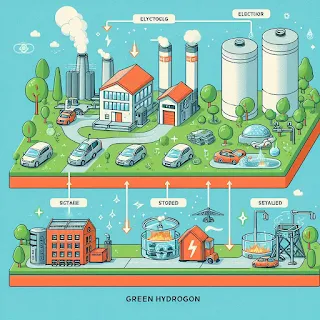

Understanding Green Hydrogen and Direct Reduction

What Is Green Hydrogen?

Green hydrogen is produced by using renewable electricity to split water (H2O) into hydrogen and oxygen through a process known as electrolysis. It is different from:

Grey Hydrogen: Produced using natural gas.

Blue Hydrogen: Like grey, but with carbon capture and storage.

Hydrogen-Based Direct Reduction

The Stegra plant will use hydrogen in a method called Hydrogen Direct Reduction of Iron (HDRI):

Iron ore is reduced using hydrogen gas.

This produces water vapor (H2O) instead of CO2.

The result is direct reduced iron (DRI), which can be further processed in electric arc furnaces.

Environmental Impact: A Cleaner Steel Supply Chain

Drastic CO2 Reduction

The Stegra project is expected to reduce carbon emissions by 95% compared to traditional methods.

It aligns with the EU Green Deal and Sweden's net-zero targets for 2045.

Water Vapor vs. Greenhouse Gases

Swapping CO2 emissions for H2O vapor not only reduces global warming potential but also contributes to cleaner local air quality.

Circular Economy Integration

Future integration with scrap steel recycling.

Renewable-powered logistics for transporting raw materials and products.

Economic and Social Impact

Job Creation and Skills Development

The Stegra project is estimated to:

Create 3,500+ direct jobs during construction.

Support thousands of indirect jobs in logistics, technology, and maintenance.

Offer new training opportunities in hydrogen engineering and renewable energy infrastructure.

Boost to Swedish Economy

Strengthening Sweden's position as a leader in clean industrial technology.

Increasing exports of green steel to environmentally conscious markets.

Stimulating local economies in Northern Sweden.

Industry Ripple Effect: Can It Go Global?

Replicability

The modular design of hydrogen-based DRI technology makes it suitable for replication in other parts of the world.

Countries with rich renewable resources—such as Canada, Australia, and Chile—could follow Sweden’s model.

Global Market for Green Steel

Demand for sustainable building materials is surging.

Automotive giants like Volvo and BMW have already committed to sourcing green steel.

Future contracts may be linked to carbon footprints, further incentivizing clean steel.

Challenges Ahead

Cost Competitiveness

Green hydrogen is currently more expensive than fossil fuels.

However, costs are expected to fall as electrolyzer technology matures and scales.

Infrastructure Demands

High electricity demand for hydrogen production.

Requires large-scale renewable energy grids and storage solutions.

Policy and Regulation

International trade laws may need adjustments to accommodate green steel certifications.

Government incentives and carbon pricing will play crucial roles.

Looking Ahead: Sweden’s Legacy in Industrial Innovation

The Stegra project is not just a technological upgrade—it is a paradigm shift. It blends climate action, job creation, and technological innovation into a cohesive strategy that could become the blueprint for future industrial development.

Sweden’s investment in hydrogen-based steel is a reminder that the path to decarbonization is both technically feasible and economically beneficial. As Stegra gears up for production, the world watches with anticipation.

Conclusion

The Stegra steel plant is more than just another industrial site—it’s a lighthouse project showing that sustainability and profitability can go hand in hand. As green hydrogen gains momentum, Sweden’s commitment to decarbonizing heavy industry may well inspire a global movement.

The future of steel is being forged in Sweden—and it’s clean, green, and hydrogen-powered.

No comments:

Post a Comment